Our electric powertrain product portfolio

We have designed our Scalable Core Technology product strategy to provide three levels of engagement. These Product Levels provide a clear pathway to production, matching customers' electric vehicle powertrain requirements with the optimal level of customisation.

Our 3 strategic product levels

01. Stock

Standard, off-the-shelf, stock products with no NRE required for the delivery of sample quantities.

Learn more03. Custom

Our scalable core technology customised to fully match specific client requirements.

Learn moreScalable Core Technology

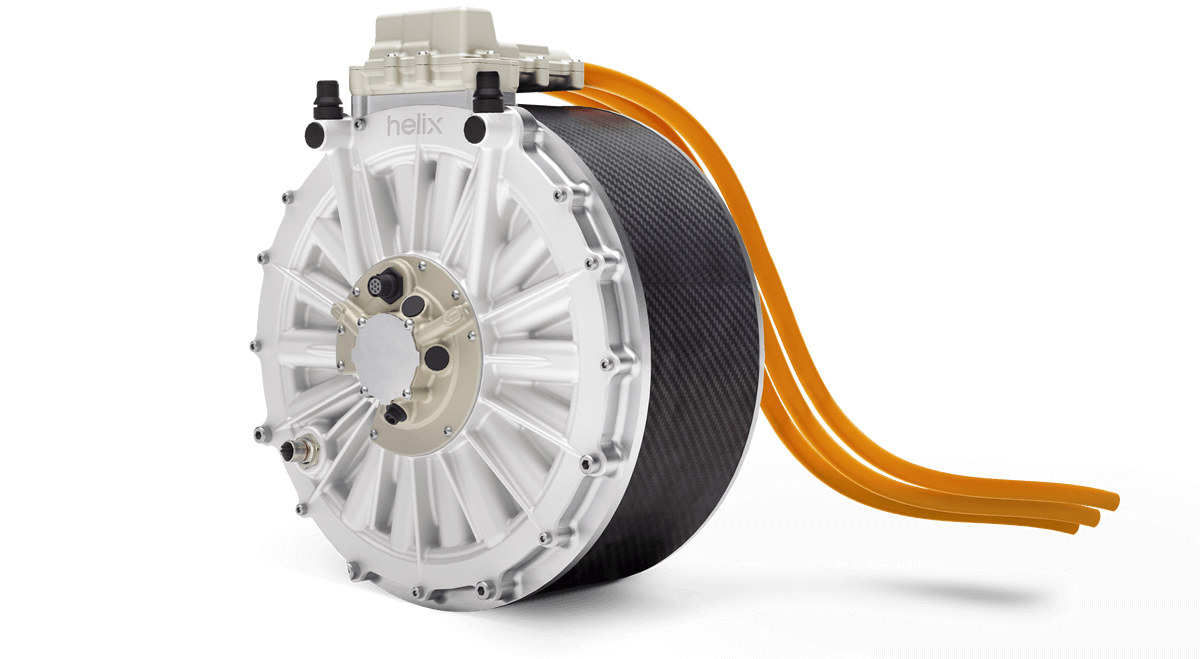

Proprietary permanent magnet rotor

- Maximum magnet flux density

- Maximum performance, minimum weight

Patented rotor-cooling

- The strongest magnets

- Low heavy rare earth content

- Stable performance

High pole-count

- Minimum ripple torque, high continuous rating

- Smoothness, low weight

Proprietary winding construction

- Durability under voltage, thermal and vibration stress

Carbon composite magnet containment

- High speed rotor

- High power

Carbon composite coolant sleeve

- Lightweight

- Brand recognition

High velocity radial & axial water cooling

- Maximum performance at high duty

- Ease of integration (no oil or air cooling)

In 2022, we consolidated our e-Drive expertise under the Helix brand. It is the culmination of 12 years’ experience building high-performance electric motors and inverters.

Between 2009 and 2015, we developed our first motors and inverters for specialist electric powertrain applications including top-level motorsport and some of the first hybrid hypercars. Their requirements were characterised by extreme duty-cycles and exposure to vibration, yet they demanded the highest possible power density. The result was a range of electric powertrain solutions offering an unmatched combination of product performance, efficiency and robustness.

Today, our motorsport heritage continues to inspire and drive our work, the relentless search for advantage among our focussed, multi-disciplinary teams powering the innovation needed to maintain motor and inverter performance leadership.

Meanwhile we have invested to increase the accessibility of our products and deliver high-performance electric powertrains to more clients at greater scale. Key to this goal, our Scalable Core Technology embodies a unique DNA, combining high performance with exhaustive design for manufacture (DFM), and the processes required for series production to the highest industry quality levels.

Scalable Core Technology is available at three product levels, Stock, Configured and Custom, enabling clients to access the right level of customisation to match their requirements with high confidence and minimum non-recurring engineering (NRE) and leadtime. Headlining this investment, we created our new Shenley Technical Centre and commissioned an IATF16949-compliant series production Flexible Manufacturing Facility (FMF).

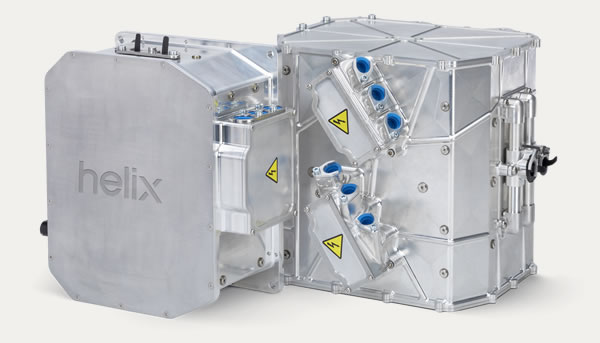

Our inverters

A combination of technologies developed and validated through R&D for application to new projects with a high degree of confidence,

Build your enquiry

Complete our quick and easy online specification form to produce personalised outline solutions for discussion.

Alternatively download and complete our form, featuring an interactive performance graph.